Predictive Acoustical Detection

Monitoring of bearing assemblies and gearboxes

PAD GmbH

PAD GmbH is the only company in Germany that manufactures devices and systems based on sound emission technology for diagnosing gears and bearings.

The use of the latest monitoring technology developed by our company has the following advantages for our devices over existing types of diagnosis:

- High reliability of diagnosis (up to 98%, as opposed to the existing 60-70%);

- High speed of information processing, which meets modern requirements

- Detection of the deterioration in the lubricating effect of the assembly at the initial stage, when it is possible to maintain its performance

Acoustic emission method

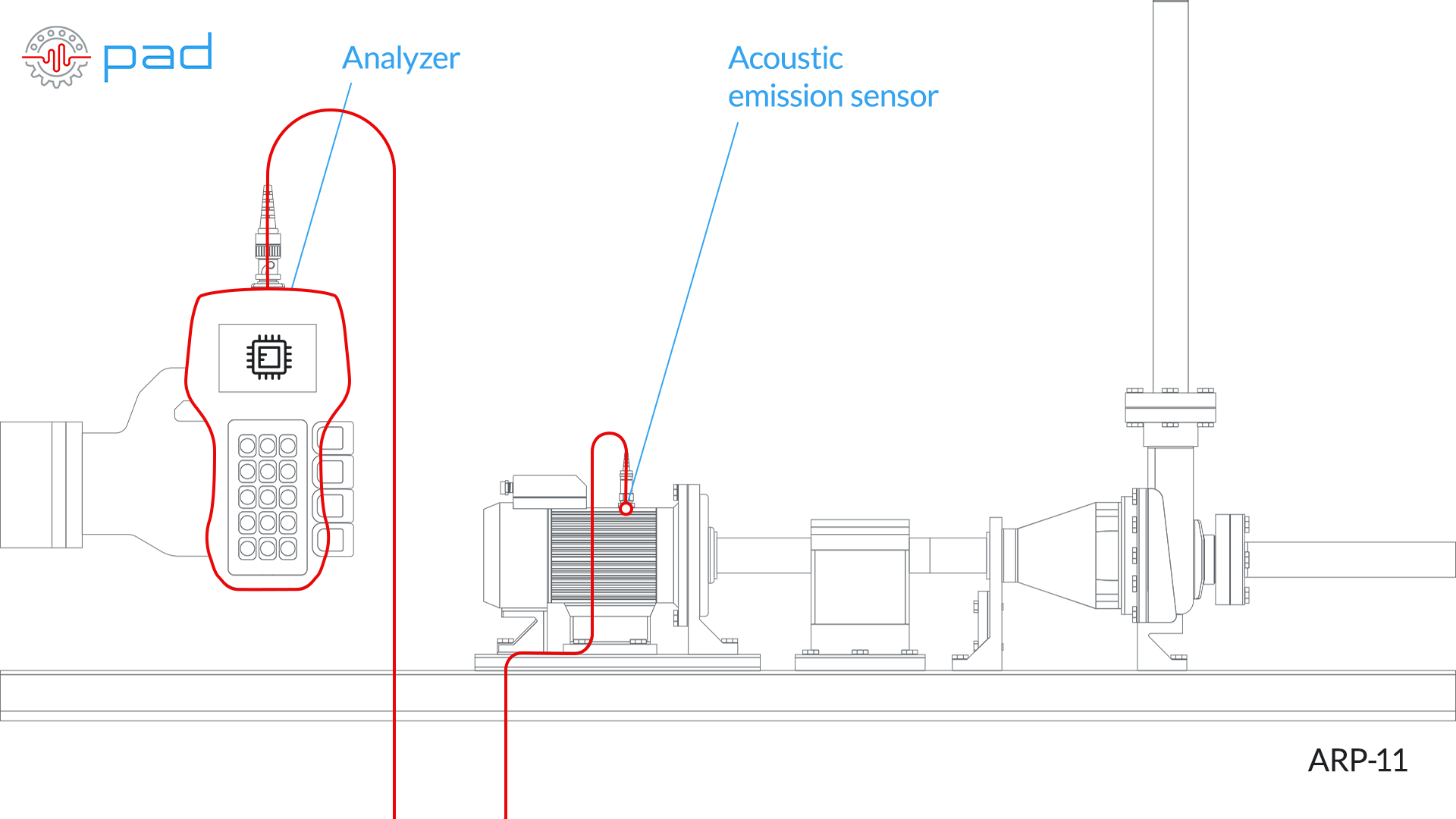

The key to the success of our acoustic and emission diagnostics is the control of the assemblies for the parameters that react most sensitively to changes in their technical state, the detection of defects in the initial stage of destruction.

The software package of systems and devices from PAD GmbH is used together with the most common operating systems and is intended to provide the user with all necessary reports on the technical status, including the announcement of the remaining service life / resource development.

Our devices guarantee the safe operation of gearboxes and storage units of devices and systems in power engineering, transportation, mining, aviation - i.e. in practically all branches of industry.

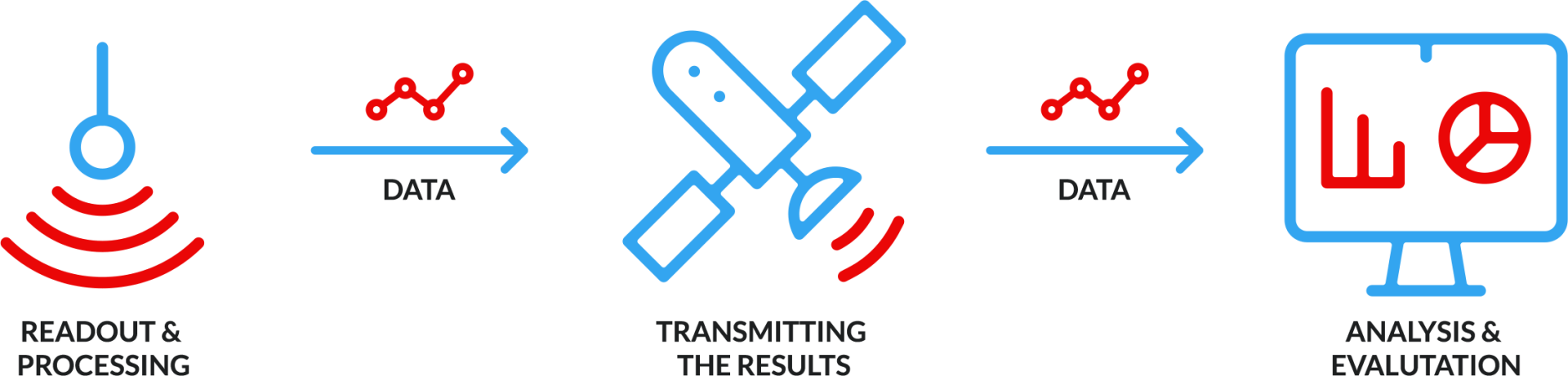

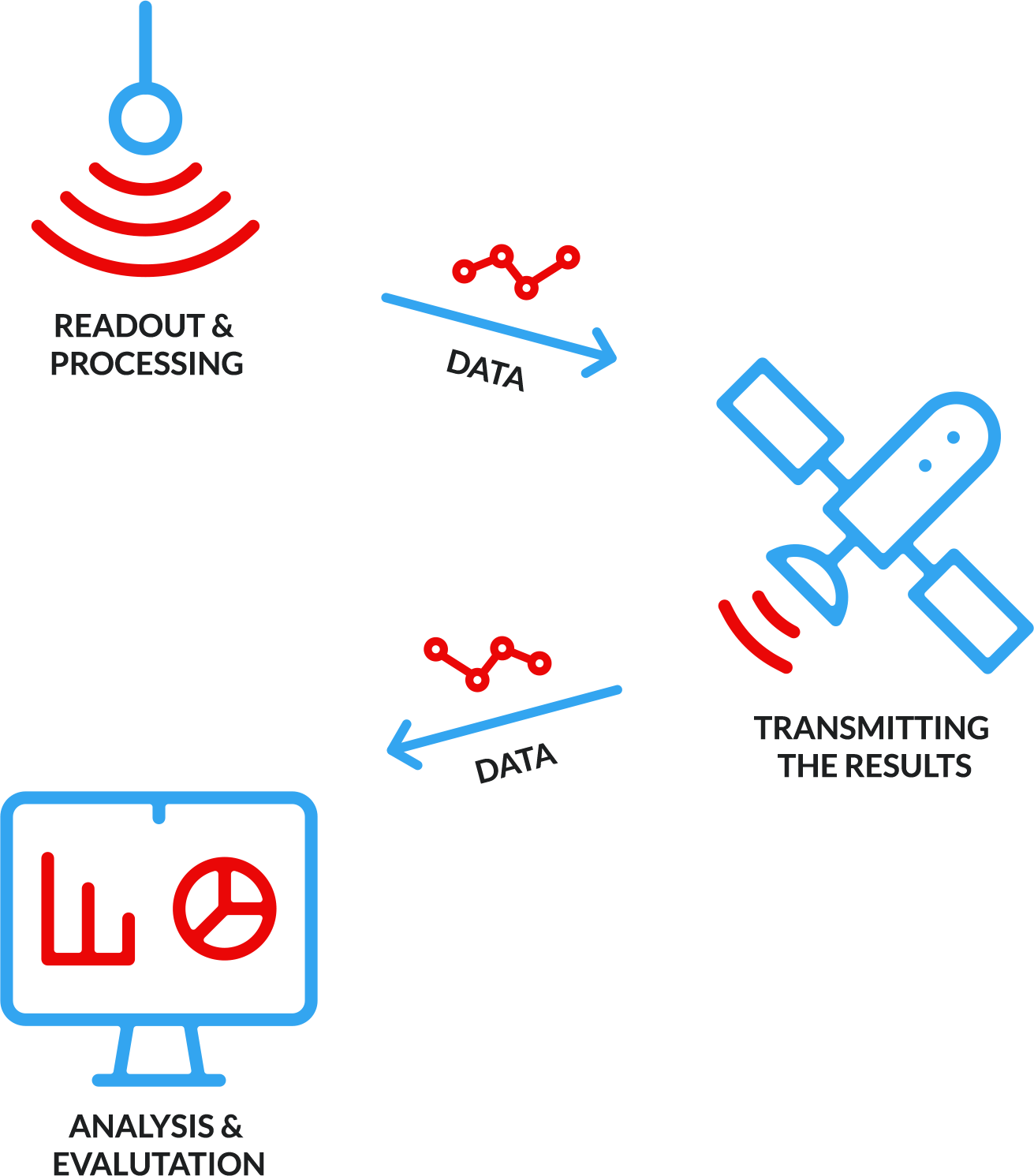

The monitoring of these assemblies with the help of data processing and modern communication systems enables with minimal costs:

- Significantly increase the service life of the assemblies.

- Reduce repair costs.

- Predictive and targeted planning and implementation of repair processes.

- Avoid unexpected failures during operation.

Our products

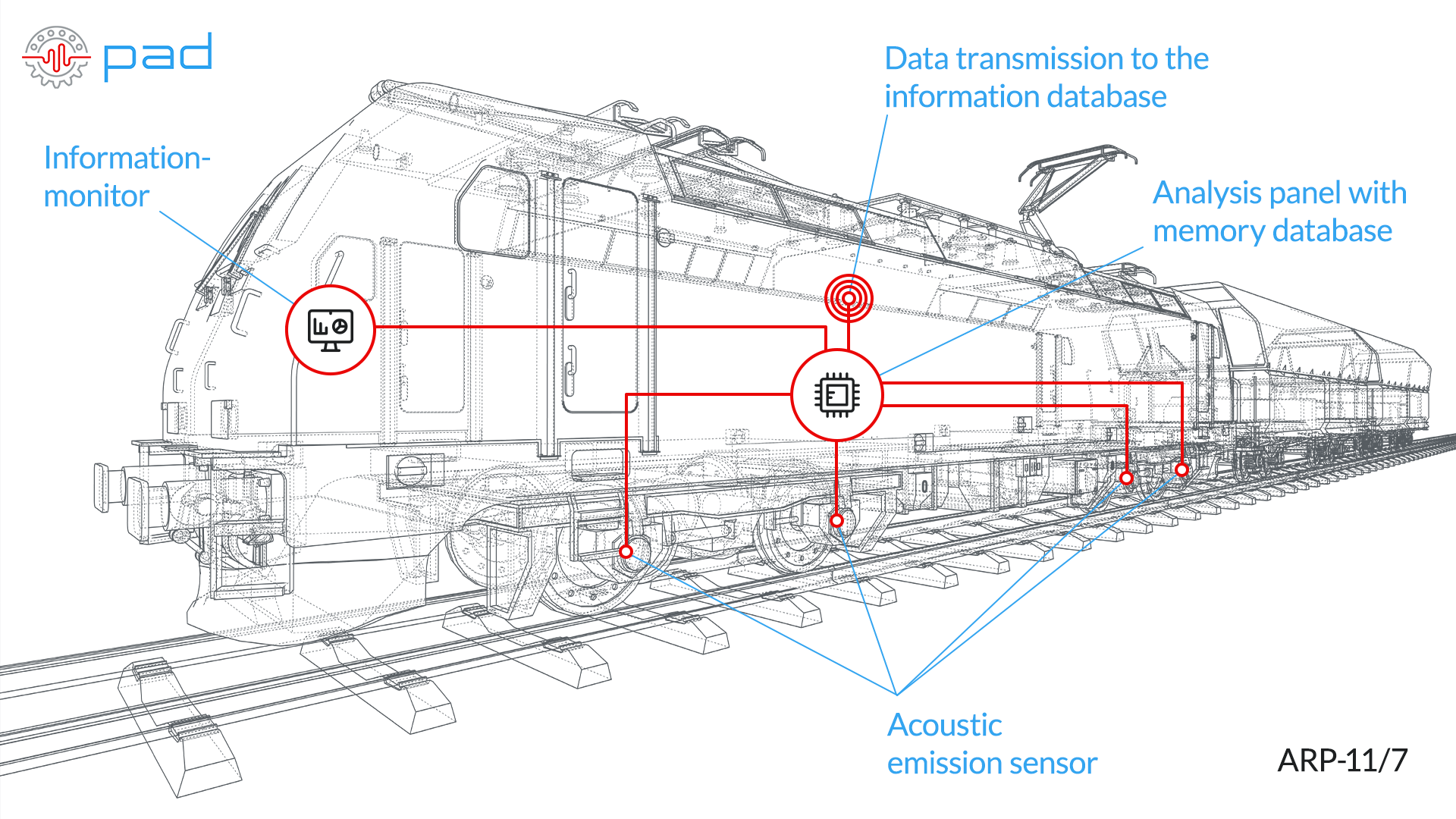

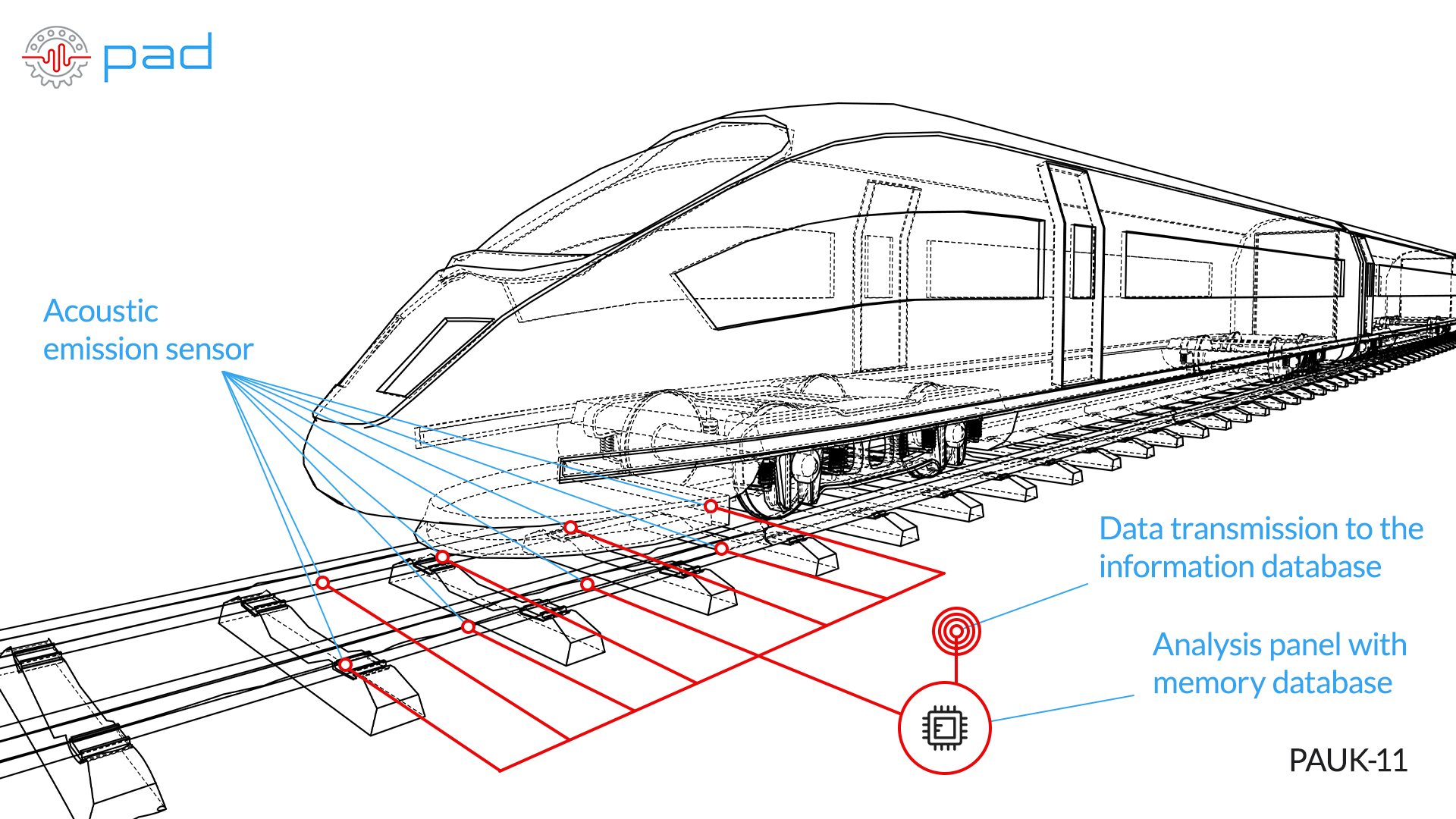

PAD offers solutions for three fields of application: a portable, single-channel readout device, a mobile multi-channel system, for example for railways and a stationary system.

Industry sectors

All of the above devices and systems have proven themselves in the following industries in Russia:

Benefits

"The damage detection of competing systems works via vibration, heat or acoustics and only detects damage at a very late stage or cannot precisely localize it."

- Direct information on the remaining service life .

- Early detection of potential sources of error before the occurrence of damage (repair options can still be initiated).

- Permanent monitoring (real time).

- Increase in the service life / service life of all system parts.

- Reduction of downtimes, repair parts and storage costs for spare parts.

- Detection of all possible error sources and types of errors.